Blast chillers are units designed for rapid cooling of foodstuffs. A commercial blast chiller is the ideal tool for optimal food preservation through rapid cooling of food. We have different ranges of Fagor Professional blast chillers that adapt to the various needs that different hospitality and hotel businesses may have.

How do blast chillers work?

Blast chillers are machines designed to quickly lower the temperature of food for preservation. The rapid lowering of temperature is important both for food safety and for maintaining the physical structure of the food.

Professional blast chillers have 2 different blast chilling processes:

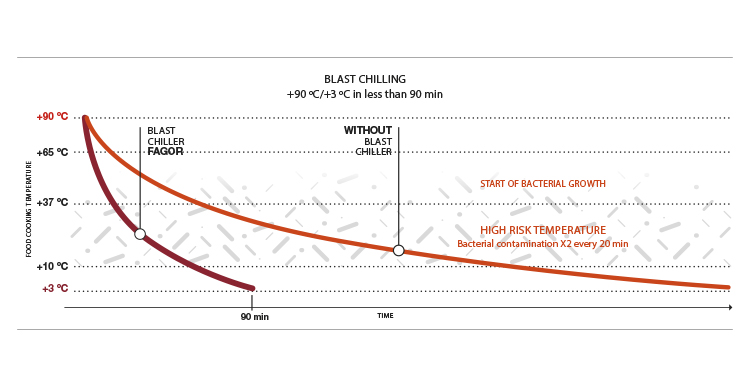

Refrigerated or positive chilling

It consists of bringing the food from 90 °C after cooking to a refrigeration temperature of +3 °C within 90 minutes, thus preventing bacteria from multiplying. Most bacteria that can cause food contamination reproduce between 60 and 10 degrees Celsius. Rapid cooling of the food reduces the risk of contamination.

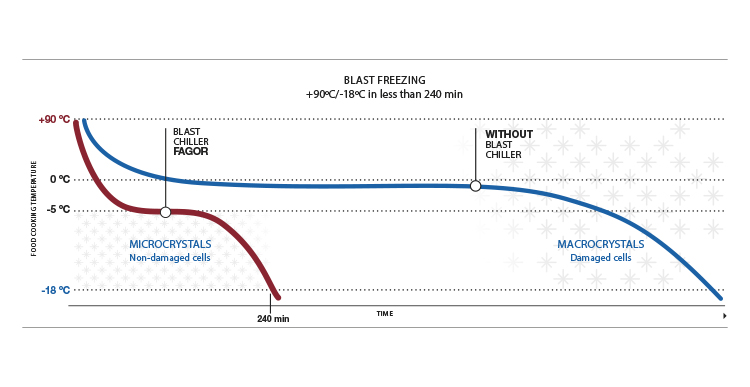

Freezing or negative chilling

The blast chilling freezing cycle consists of reducing the temperature of freshly processed food to -18 °C in a time of 4 hours, thus achieving a very fast freezing of food, avoiding the formation of macrocrystals, preventing the food from losing up to 20 % of its structure when thawed, preserving its structure.

Chilling cycles

Fagor professional commercial blast chillers have 2 types of blast chilling cycle, both for freezing and refrigerated blast chilling:

-

Soft cycle (standard): It is a cycle suitable for soft, "light" or delicate foods of small size or volume. The soft freezing cycle freezes the food very uniformly, making it suitable for foods that should not be subject to sudden changes in temperature, or which contain a variety of ingredients.

-

Hard cycle (intensive): It is suitable for high density or heavy foods, as well as for preparing food for packaging. The hard freezing cycle is the ideal cycle for freezing semi-finished foods or semi-prepared dishes. It is also suitable for raw foods. It allows you to keep frozen products in stock for a long time, for use throughout the year.

Advantages of using a blast chiller vs. a freezer

The difference between commercial blast chillers and freezers is the speed at which the food is cooled. This fact has several advantages that make it important for restaurants, bakeries or any other type of hospitality service to buy a blast chiller.

The main advantages that the different Fagor Professional blast chillers provide are as follows:

Hygiene: the rapid drop in temperature prevents the reproduction of micro-organisms in freshly prepared food.

Quality: the rapid drop in temperature allows the humidity in the food to remain unchanged and prevents normal bacterial growth. Our blast chillers are also ideal for preserving fresh and raw foods such as fish, crustaceans, vegetables, bread and semi-finished foods such as fresh pasta and sauces.

Work optimisation: blast chillers make it possible to prepare a large quantity of product which, once blast chilled, can be consumed within the following 5-7 days. Advance planning significantly improves the purchasing of raw materials, the organisation of the work in the kitchen and the variety of the menu.

Time saving: with the simple operation of food regeneration it is possible to serve a wide range of dishes in a very short time. Blast chillers increase production capacity by reducing personnel costs, with significant advantages in terms of cost-effectiveness and time.

Range of Fagor Professional blast chillers

The products we offer for Cook & Chill solutions are adapted to different needs.

Compact blast chillers: compact blast chillers of different sizes, easy to clean and handle, adapted to the needs of each customer.

Concept blast chillers: specially designed for catering companies or restaurants using the Cook & Chill system, they are an indispensable element in the cooking-chilling-regeneration chain.

Cook&Chill solution blast chillers: the combined use of ovens and blast chillers allows you to be more efficient, as it makes it easier for you to programme your work in the kitchen. The use of blast chillers with combi ovens results in less waste, time savings and a product that is served at the right time.