What is a commercial boiling pan and what is it for?

It is a collective cooking machine that allows the preparation of large volumes of food such as stews, soups and stocks by controlling the heating by means of an energy regulator. The heat needed to prepare the food can be generated externally by steam, by direct fire with natural gas or propane and can also be generated by electrical heating elements.

The commercial boiling pan is used in food processing places of all kinds, including the cooking of poultry and meat, fruit and vegetables or sweets. They are also used in kitchens of bars and restaurants, hospitals, hotels and country houses, canteens of large companies and other places such as laboratories and the brewing industry where the sale of commercial boiling pans is increasing.

What is the origin of the boiling pan?

The word marmita [boiling pan] comes from the Old French "marmite" meaning hypocrite, which can be applied to the vessel because it hides its contents. Originally, the boiling pan hung from the chimney and was used both to boil water for washing and to prepare soup or stew. Later on, the use of the boiling pan was relegated exclusively to the preparation of soups and stews, one of the best known being the one made by Basque sailors, called marmitako.

Types of commercial boiling pans

The types of boiling pans are defined by the energy source used, electricity, gas or direct steam. Direct steam boilers provide higher efficiency and cook faster with a larger capacity than gas and electric boilers, and volumes vary from 10 to 500 litres, although the most common for large kitchens is around 300-400 litres.

- Steam boiling pans: These models use steam energy to transfer heat by conduction to the food product inside. Typically, steam boiling pans have an enclosed chamber so that the transfer of heat energy is from the bottom and from the sides.

The operating pressures of these devices are around 50 PSI, resulting in a uniform temperature of the entire coating surface.

- Electric boiling pans: The energy source is electricity, and the heat is produced by heating elements controlled by a thermostat. Where a gas supply source is not available, these can be ideal as they only need to be connected to the electricity grid and do not require as much maintenance and rigorous safety monitoring as gas-fired ones.

- Gas boiling pans: The heat source comes from the burners, directly from the flame. The flame heats the bottom of the vessel and heat is transferred as the temperature of the water in the vessel rises. The price of this commercial boiling pan usually depends on several factors, but the maintenance compared to electric boiling pans is higher due to the safety measures they incorporate.

Fagor Professional Kore 700 commercial kitchen boiling pans

When selecting and choosing the type of commercial boiling pan for the hospitality industry, it is important to know which brand it is. At Fagor Professional we have extensive experience in the manufacture of professional boiling pans for restaurants.

Fagor Professional models are a guarantee of quality. You will know that you are getting the best possible technology, given the hard work and professionalism of the people involved in the process of creating these highly productive machines.

In general, Fagor Professional boiling pans offer optimum performance thanks to a high power of up to 17 KW, taking safety into account as well as quick, easy and perfect cleaning.

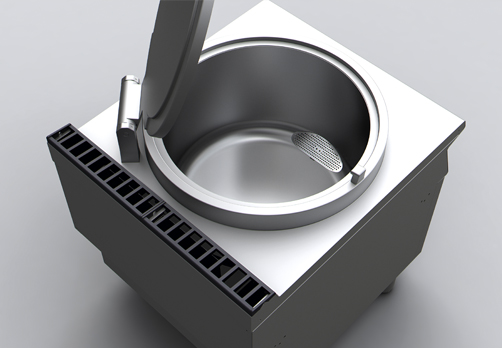

In terms of safety and cleanliness, some of the main features of the Fagor Professional models are that their tank is integrated into the worktop by robotised welding and is made of stainless steel with a 2 mm thick stainless steel base.

It can be filled with hot or cold water by means of solenoid valves activated by a single switch on the front panel, and it can be emptied by means of a safety tap with an athermic material handle, which is safe and effortless to operate. They have a drainage hole to channel possible spillage of liquids together with a filter made of stainless steel, robust, reliable and easy to remove. The controls with protective support base have a system against water infiltration, and the degree of protection against water is IPX5.

The direct-fired boiling pan models use a high-performance, stainless steel tubular burner with optimised combustion and sequential operation. The energy regulator control allows for slower cooking times. Heating of the burner at the base of the boiling pan is evenly distributed, resulting in gradual heating of the contents of the vat It offers the possibility of regulating the heating sequence of the burner by means of different degrees of adjustment.

The indirect-fired or bain marie boiling pan models have an enclosed chamber around the pan, with an automatic filling system and triple safety features: pressure switch for pressure control in the chamber, thermostat to limit overheating in the chamber and safety valve for overpressure. The chamber is automatically purged, and the heating at the bottom of the boiling pan acts on the water in the surrounding chamber, so that it heats up with the saturated steam generated to a temperature of 107 ºC.

The gas boiling pan models are fitted with a high-performance, stainless steel, combustion-optimised tubular burner ignited by a spark train. The energy regulator control allows for lower water and energy consumption.

Finally, the electric boiling pan models are heated by a heating element located in the lower part of the bain marie chamber. The heating is controlled by means of an energy regulator and pressure switch.